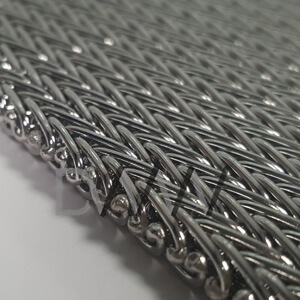

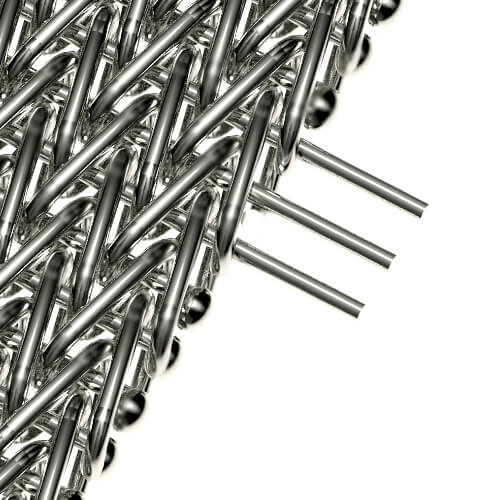

In order to obtain a very closely woven mesh belt it is possible to multiply the number of spirals and cross-rods per pitch and this construction is known as Cordweave or compound weave belting.

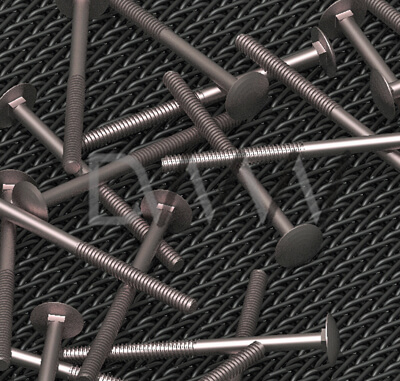

This type of belt is ideally suited to the conveying of very small items such as rice, grain or very small fasteners.

Where necessary side-plates and cross flights can be fitted where goods are being transported up an incline or when conveying heavy loads.

Its precision manufacture helps to minimise belt stretch and edge sagging, thus ensuring an extended belt life in many friction driven applications.

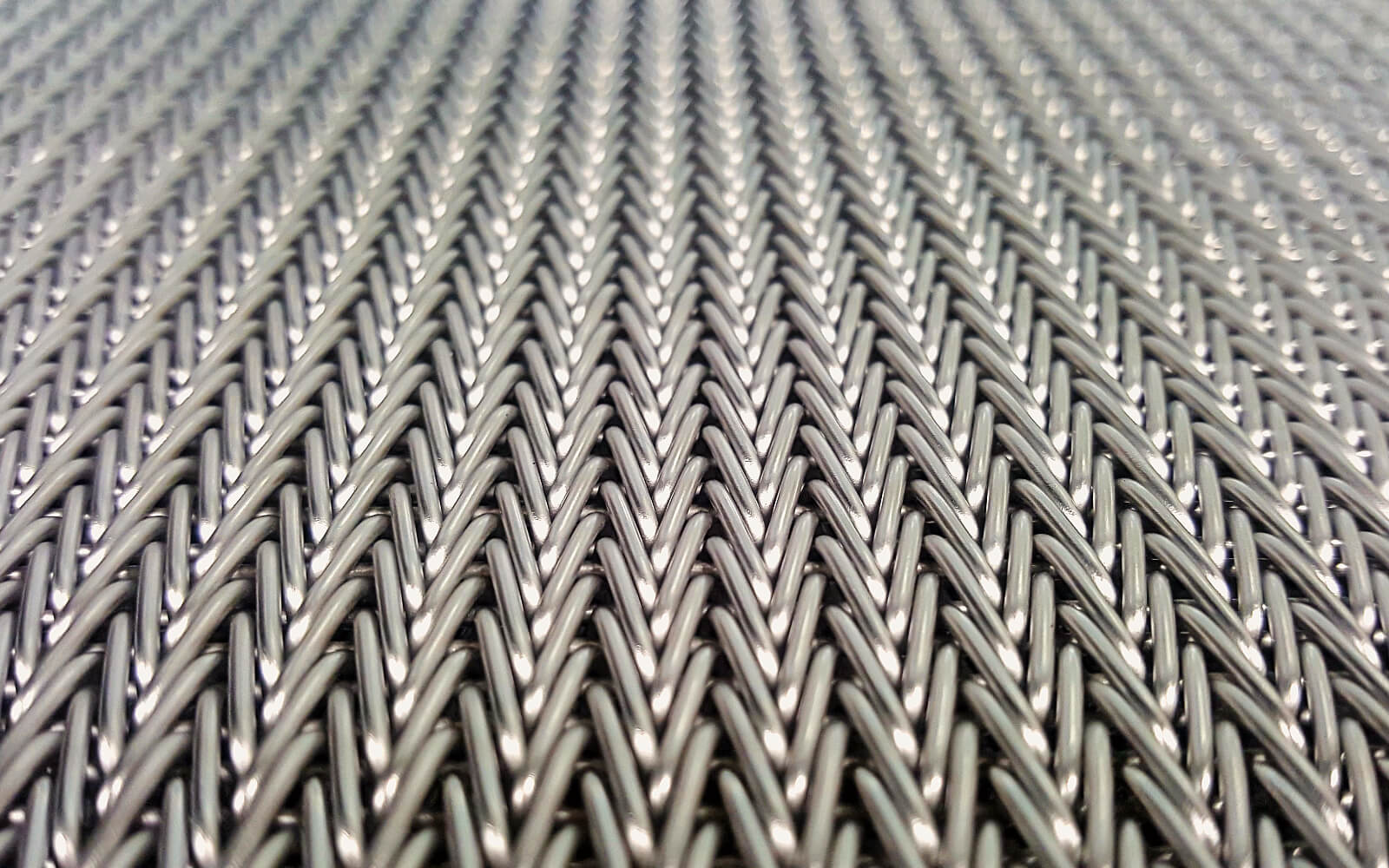

This compound balanced weave specification is extremely smooth and its high density ensures that heat is transferred uniformly across the entire width of the belt at elevated temperatures.

Widely used for baking bands this weave of belt can also be manufactured with flattened spiral wires for an even smoother, more stable surface when conveying unstable objects.

This design of belt is predominantly used in the baking industry for processing, biscuits, crackers and a variety of snack food products.

Cordweave3-3 pins per spiral

Cordweave4- 4 pins per spiral