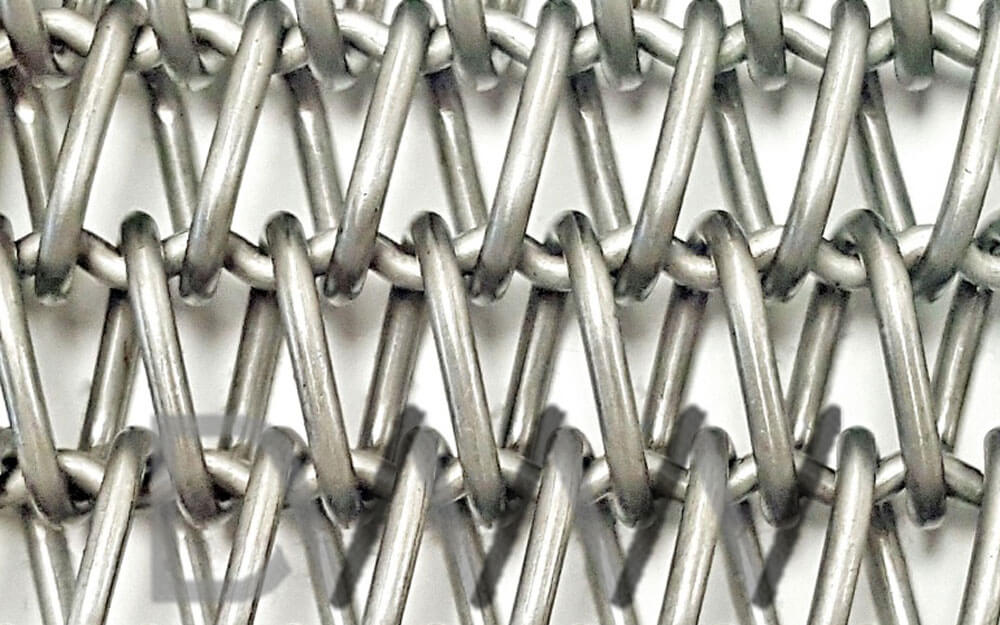

The Balanced spiral style of belting is the most common design for friction driven belts.

It is suggested for first consideration in all applications unless particular design requirements dictate the use of another type of belt.

Providing the widest variety of strengths, aperture sizes, wire diameters and surface characteristics the design of the belt means that it is easily tracked and may be used at elevated temperatures.

Mesh choice is virtually unlimited but it is dependent upon the requirements of the intended application, product size and weight, support considerations, as well as the operating temperature.

The balanced nature of this particular product, comprising of clockwise and anti-clockwise spiral, allows for optimum tracking qualities conversant with straight-running processes.

BS – The standard straight running design of single right and left-handed coils joined by crimped cross wires to retain the original belt shape is available in wire diameters from 0.8mm to 4mm and aperture sizes ranging from 3mm to 25.4mm.

BSPD – Balanced spiral positive drive belts are manufactured so that their apertures engage with the teeth of their relevant positively driven sprockets. This ensures straight running characteristics as the belt becomes positively driven. This belt is available in a variety of aperture sizes and wire diameters and can be manufactured in a wide range of materials.

Extremely tight product transfers can be achieved using this particular style of belting and it is also less expensive than the equivalent chain edged driven mesh belts.

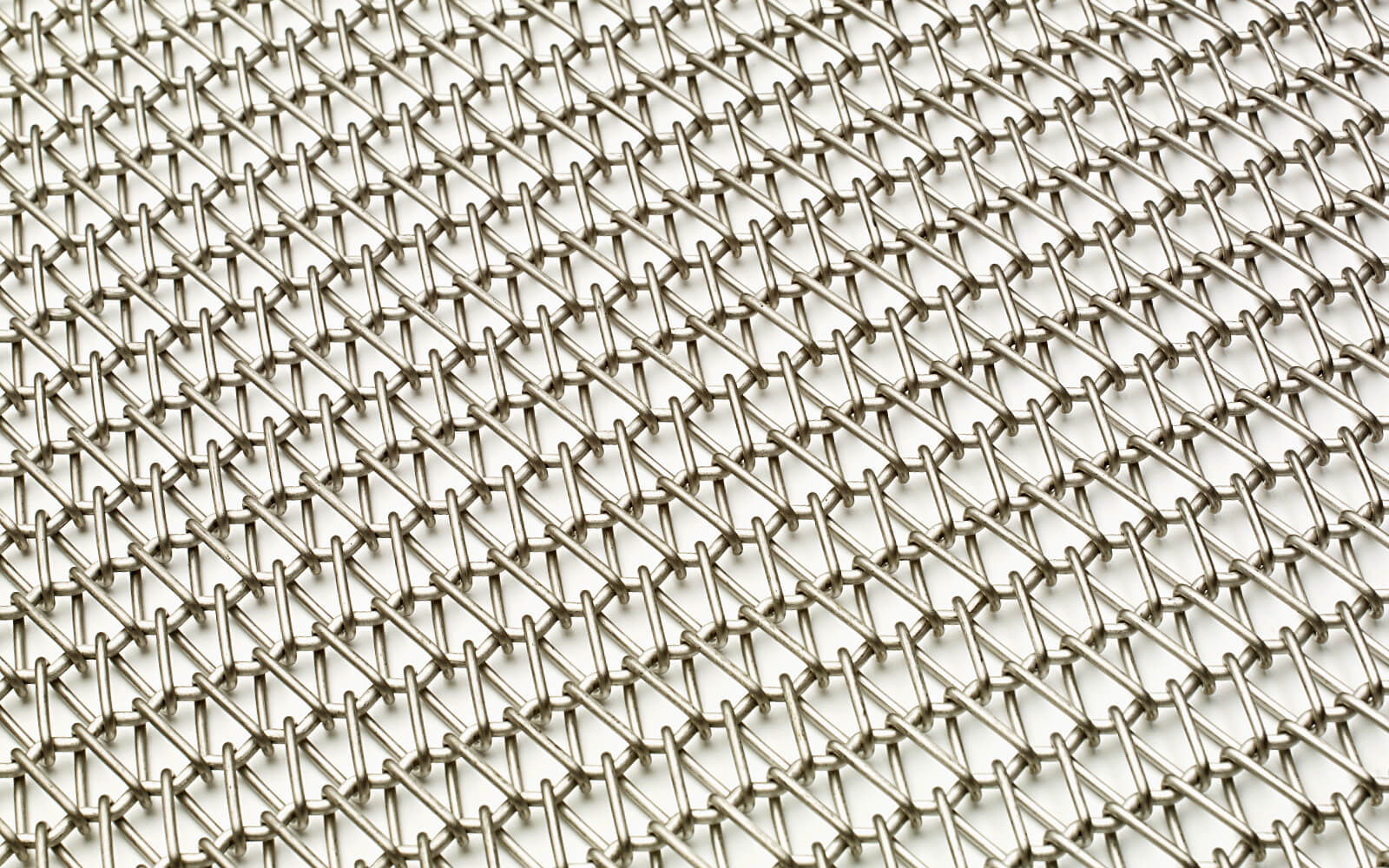

BSF –This balanced spiral belt uses flattened wire for the spirals and round wire for the crimped cross-rods. This design of belt creates an extremely flat surface for transporting goods requiring a more stable platform for conveying and greater product support such as the transportation of glass bottles and containers in the lehr belt industry.

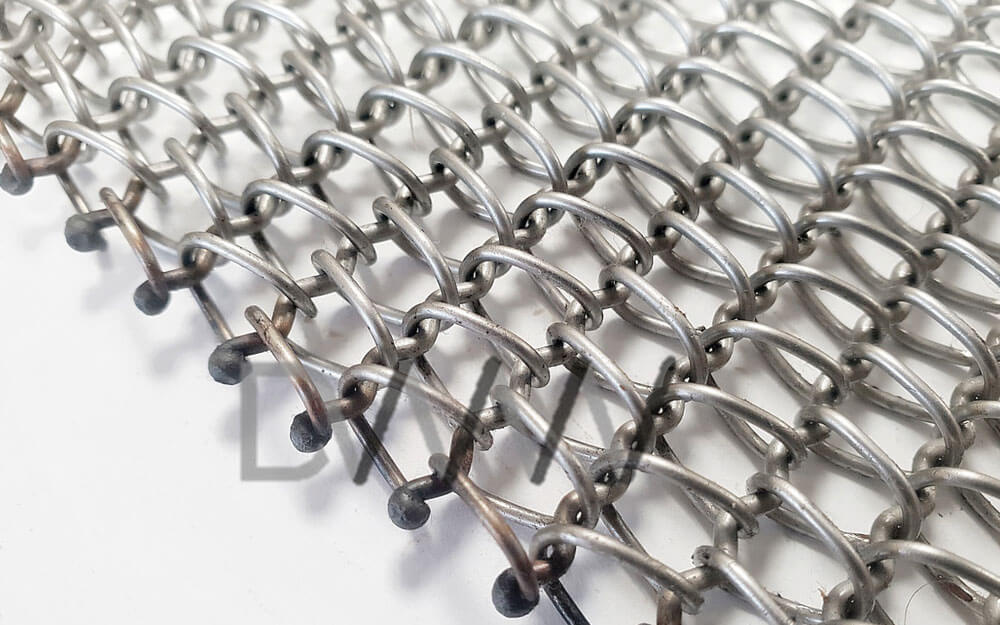

IBS – Comprising of single right and left hand spirals this design is constructed with straight cross-rods allowing for a much tighter lateral pitch. This style of belt is ideal for conveying small components and conveying heavy loads. It can be used at elevated temperatures and is predominantly used in the manufacture of wire mesh lifting slings.

Chain Driven – Chain Driven Product Page

DB-Double Balanced-Double Balanced Product Page

Welded

Laddered (Not available on all specifications)

U-Pin (Not available on all specifications)