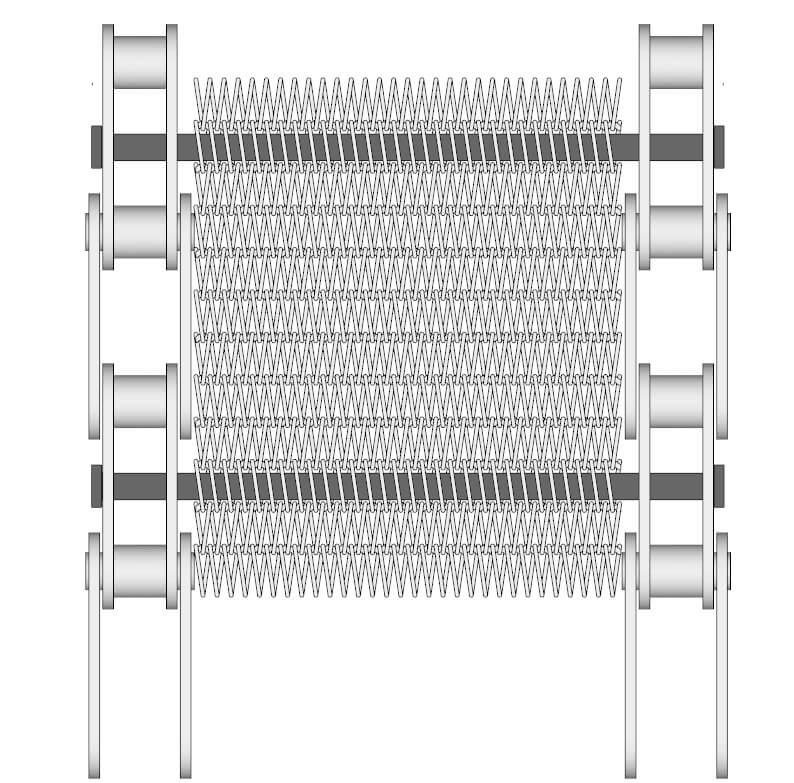

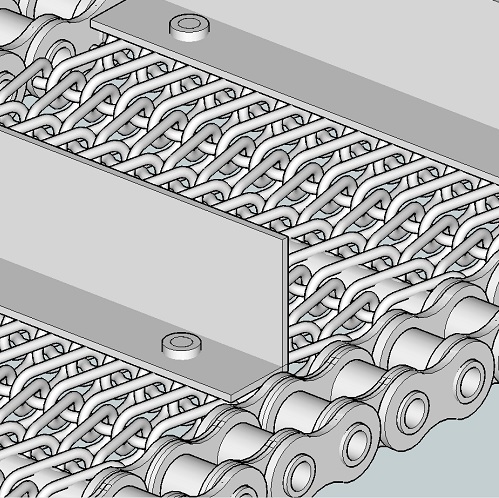

Chain driven woven wire mesh belts should be considered whenever timing, transfer or positive belt drive is important. This includes applications incorporating inclined travel, heavy loads, long distance conveying or when transporting items through quenching liquids, cooking oils or similar slippery environments.

A multitude of specifications are available depending upon the size of the product being transported.

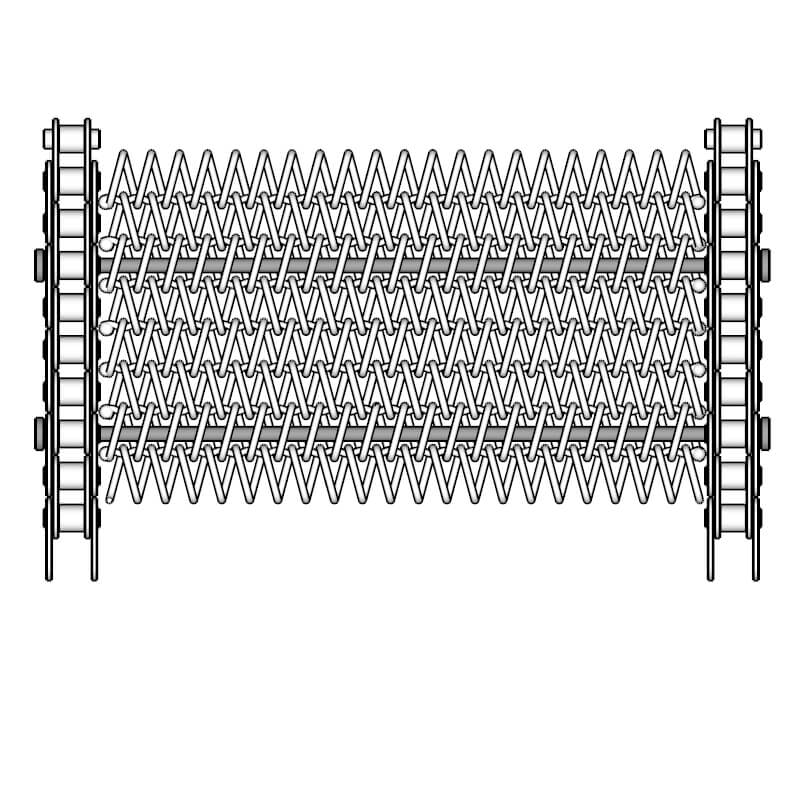

The balanced spiral weave belt should be given first consideration for chain edged belts as it is economical, comes in a wide range of wire diameters and aperture sizes and is suitable for the majority of applications.

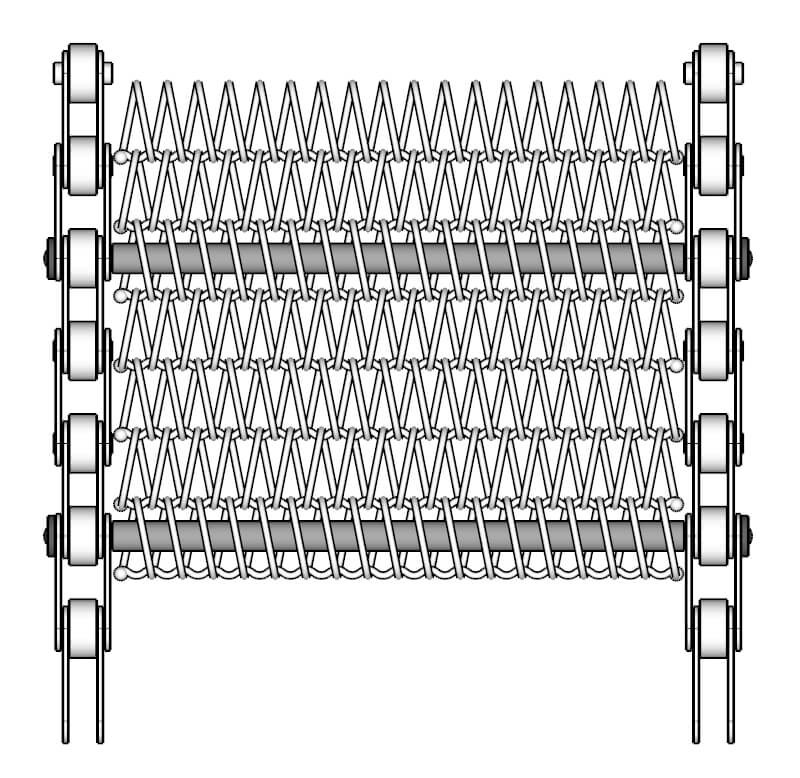

A conventional weave belt is easier to clean due to the weave having unobstructed openings.

Chain driven belts also facilitate the addition of special features such as side plates and cross flights where necessary.

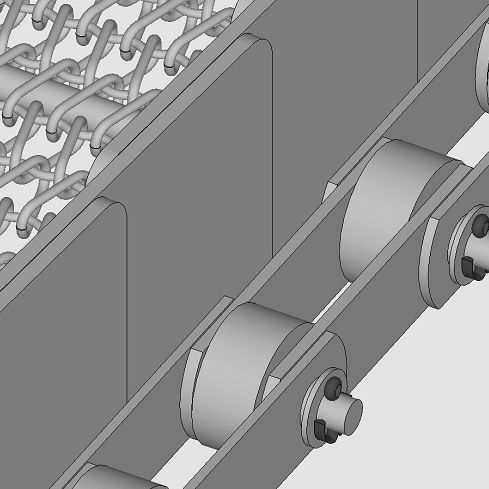

Chain selection is usually determined by the strength and speed of the belt required in conjunction with the loading and operating temperature of the process.

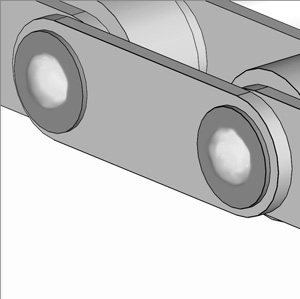

Transmission Chain

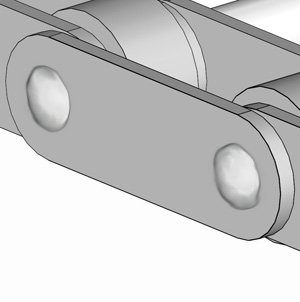

Conveyor Chain

Freezer Chain

Sideplates

Crossflights

Welded Washer

Welded Rod Selvedge

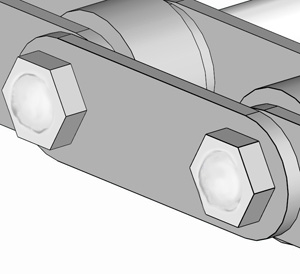

Welded Nut Selvedge

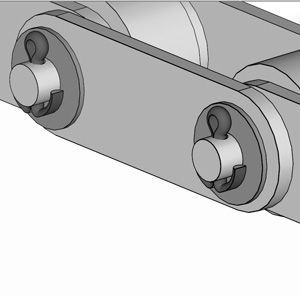

Split Pin And Washer